Headline

The Heart of American Solar

Since 1999, First Solar has called northwest Ohio home, producing American-made thin film solar panels at its vertically integrated manufacturing facilities. First Solar has grown and invested more than $2.8 billion in its three-factory Ohio footprint, with an additional $1.3 billion investment in expanding its US manufacturing capacity, including a new facility in Alabama, to over 10 gigawatts by 2026.

First Solar has grown from just 50 jobs and 74,000 square feet of space in 1999 to an expected 3,000 direct jobs and 6.5 million square feet of space in four states by 2025.

By strategically building and sustaining US supply chains, First Solar is investing in America and enabling growth and jobs not just for the solar industry but for other US industries such as glass, steel, mining, and transportation, to name a few.

What’s more, the company’s commitment to Responsible Solar means producing solar technology that embodies sustainability and has zero tolerance for forced labor in its manufacturing or supply chain, while meaningfully enabling America’s energy transition.

This is about more than solar. This is about a resilient, self-reliant America.

Glass to Module in 4.5 Hours

With the expansion of its manufacturing capacity in the US, which is expected to reach 10 gigawatts by 2026, First Solar expects to produce an American-made solar panel every 1.6 seconds. Each panel is proof that it is possible to out-innovate and out-compete China by manufacturing in America, for America, using American materials.

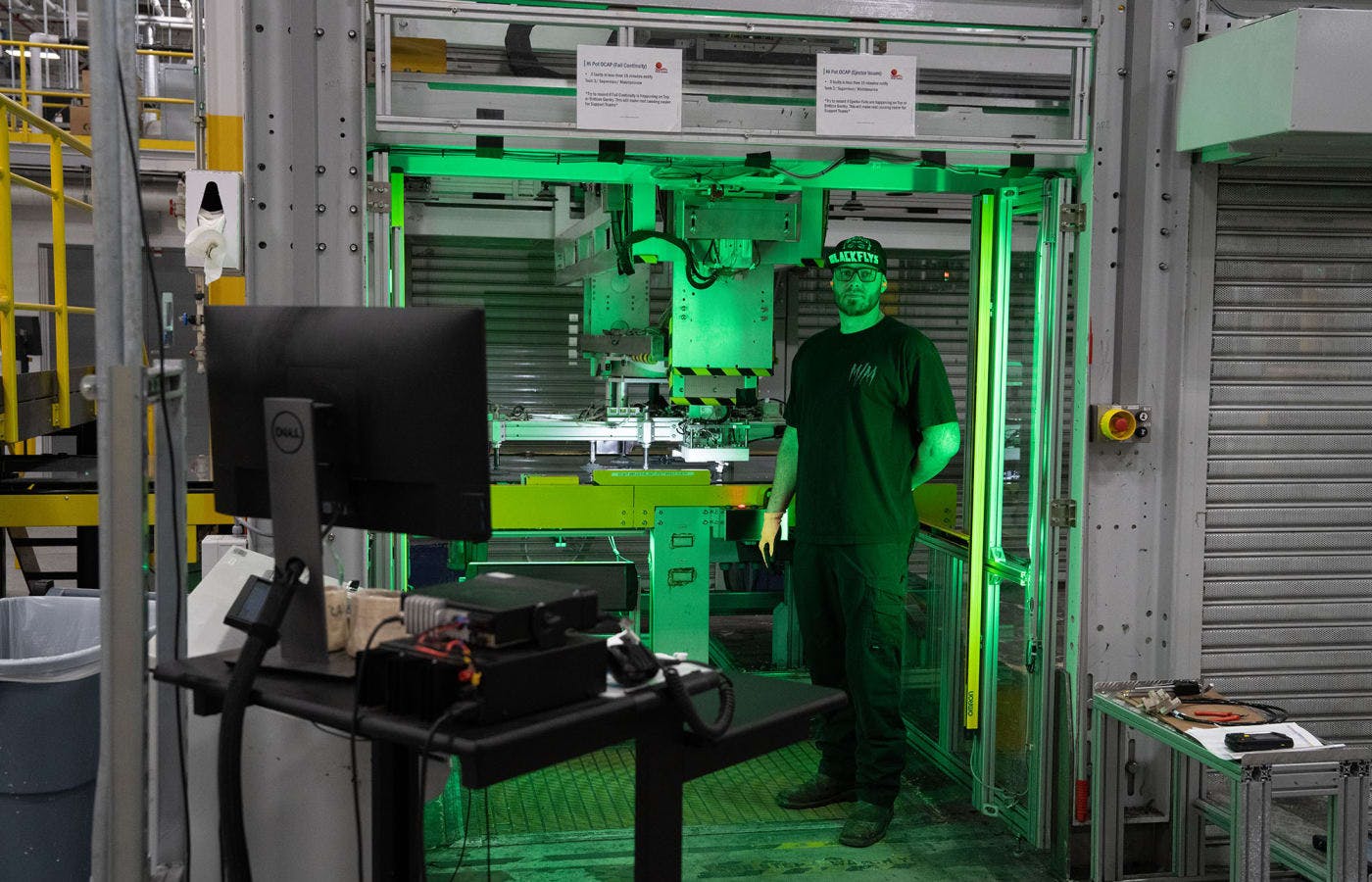

Using a thin film semiconductor rather than crystalline silicon, First Solar’s fully integrated, continuous process enables full quality control under one roof, converting a sheet of glass into a fully functional solar panel in just 4.5 hours.

First Solar’s manufacturing process uses 98% less semiconductor material than traditional crystalline silicon solar panels and each solar panel uses a layer of semiconductor that is just three percent the thickness of a human hair.

"My sister just died a few weeks ago, so I’m preparing for the holidays without her, but I've gotta keep on pushing for my kids.

I’m a father of two now, so that is my priority.

This job works well with my schedule, I only have to work half the year with the way the shifts work.

My sister liked me working here because she got to see me more. She told me I should stay at it because she could see how much I used to stress at my other job working in the auto manufacturing industry. A couple of weeks before she died, she said stay at it because she saw I was happy."

Christian Doyle | Production Operator | First Solar Manufacturing Plant 2, Toledo, Ohio

Responsible Solar

First Solar’s uniquely American solar technology, developed in California and Ohio, embodies sustainability and responsibility towards people and the planet. It's why the company has a long history of establishing benchmarks in recycling, responsible supply chain management, transparency, and its technology’s ultra-low carbon and water footprint.

First Solar is the only one of the world’s 10 largest solar manufacturers to be a member of the Responsible Business Alliance (RBA), the world’s largest industry coalition dedicated to supporting the rights and well-being of workers and communities in the global supply chain.

In 2022, First Solar’s Ohio manufacturing complex achieved Platinum status in a Responsible Business Alliance (RBA) Validated Assessment Program (VAP) audit, the highest possible rating. The audit covered the full scope of the VAP, including fair labor practices and human rights, health and safety measures, environmental performance, business integrity, ethics, and supporting management systems.

First Solar’s technology has the lowest carbon and water footprints of any commercially available solar panel today, and the company is the first photovoltaic manufacturer to have its product included in the Electronic Product Environmental Assessment Tool (EPEAT) global registry for sustainable electronics.

"I started here when my daughter was 4, this week she's going to be 18. She wears all my old First Solar shirts to school, she just got accepted to university and she wants to be a psychologist.

This is the heart of the line right here where you put all the material to the plate, the double-sided tape, the lead foil and the bus bar, it all comes together here.

I'm the lead trainer down here, so I've been training people for the new plant that’s being built."

Tammy Kyles | Bussing Production Lead | First Solar Manufacturing Plant 2, Toledo, Ohio

"I've been a Pittsburgh Steelers fan since I was five because I'm a daddy’s girl. He's always been a Steelers fan. He came out here one time for a family day and he got to walk through the plant, he was amazed

that I could handle working in a factory like this. I don't know, maybe he

pictured me sitting in an office somewhere.

I've been here 17 years now. I like to say I

help produce energy. The type that you don't have to worry about running out of

it. I work on the sub module and finishing."

Kelli Amato | Production Operator

First Solar Manufacturing Plant 2, Toledo, Ohio

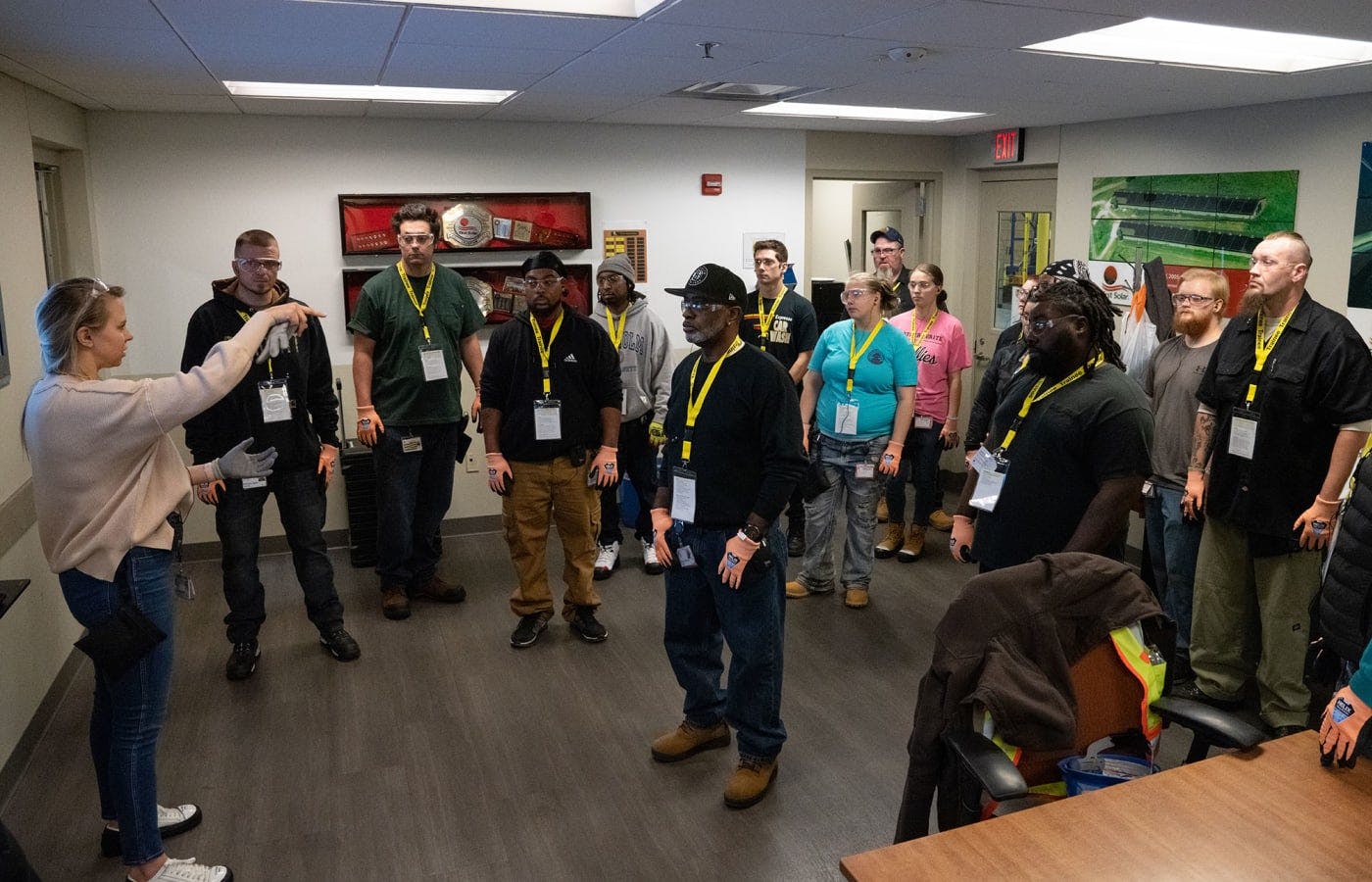

"When I started at First Solar in manufacturing, I also started to go to school for business administration with a minor in IT, and the company is paying for 100% of it.

Now I'm a forecaster, part of the supply chain, I still work closely with manufacturing to fulfill all the orders according to what each customer needs for wattage that each of the panels produce."

Brett Catchings | Forecaster

First Solar Manufacturing Plant 2 | Toledo, Ohio

Keeping it Rolling

Global advanced manufacturing equipment maker, Grenzebach’s facility in Newnan, Georgia, provides some of the tools that help First Solar transform raw materials into leading-edge photovoltaic technologies. Supplying glass conveyor equipment, Grenzebach’s engineers, factory workers, and technicians have helped First Solar factories reach industry-leading levels of efficiency in moving large sheets of glass with precision and speed.

"I'm a husband, father, and for the last three seasons a softball coach. Welding puts food on the table - smoked ribs on the

grill, mac 'n' cheese, and baked beans.

I'm a welder fabricator that has been here for 20 years. I'm making safety guards to protect people from glass on the manufacturing

line."

Lee Evans | Welder | Grenzebach, Newnan, South Carolina

Closing the Loop

First Solar is the only solar manufacturer with global in-house solar panel recycling capabilities and more than 15 years of experience operating high-value photovoltaic recycling facilities on a worldwide and industrial scale.

First Solar operates an advanced recycling program that provides closed-loop semiconductor recovery for use in new solar panels while also recovering other materials, including aluminum, glass, and laminates.

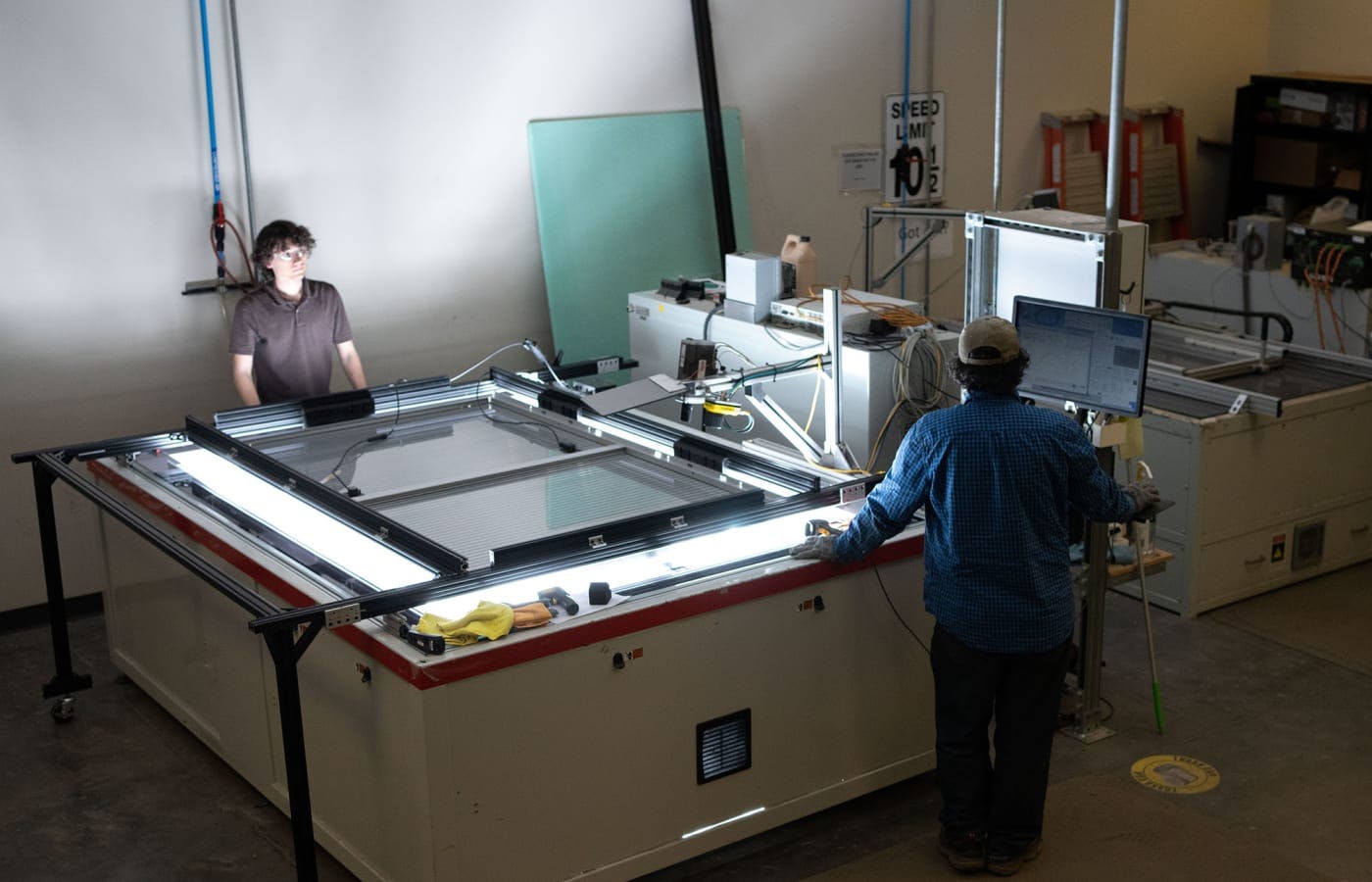

Field Tested

To ensure its panels can perform even in extreme weather conditions, First Solar has multiple test sites around the globe, including in Arizona and Ohio. The company's employees at these sites review solar panel performance, host customers, and test new installation means and methods.

"Being on a competitive team in soccer has really helped me in a competitive workplace, knowing when to take the lead and when to just listen.

I'm kind of the first person you speak to if you're trying to buy solar panels at First Solar. For me, the past two years, have been spent trying to be the voice of the customer back to the research teams. I used to be a

customer before I worked at First Solar, so that's helped me in my sales

job."

Erin Pincombe | Technical Sales Manager (USA & Canada) | First Solar Research and Development Site, Mesa